TRANSFORMER

LE CHANVRE

du chanvre

de la chanvrière

En France, 7 chanvrières réalisent la première transformation du chanvre. Elles sont approvisionnées par 1 550 producteurs avec lesquels elles signent des contrats d'approvisionnement de 3 à 5 ans. Employant 300 personnes, ces chanvrières ont transformé plus de 141 000 tonnes de chanvre en 2023.

Françaises

du chanvre

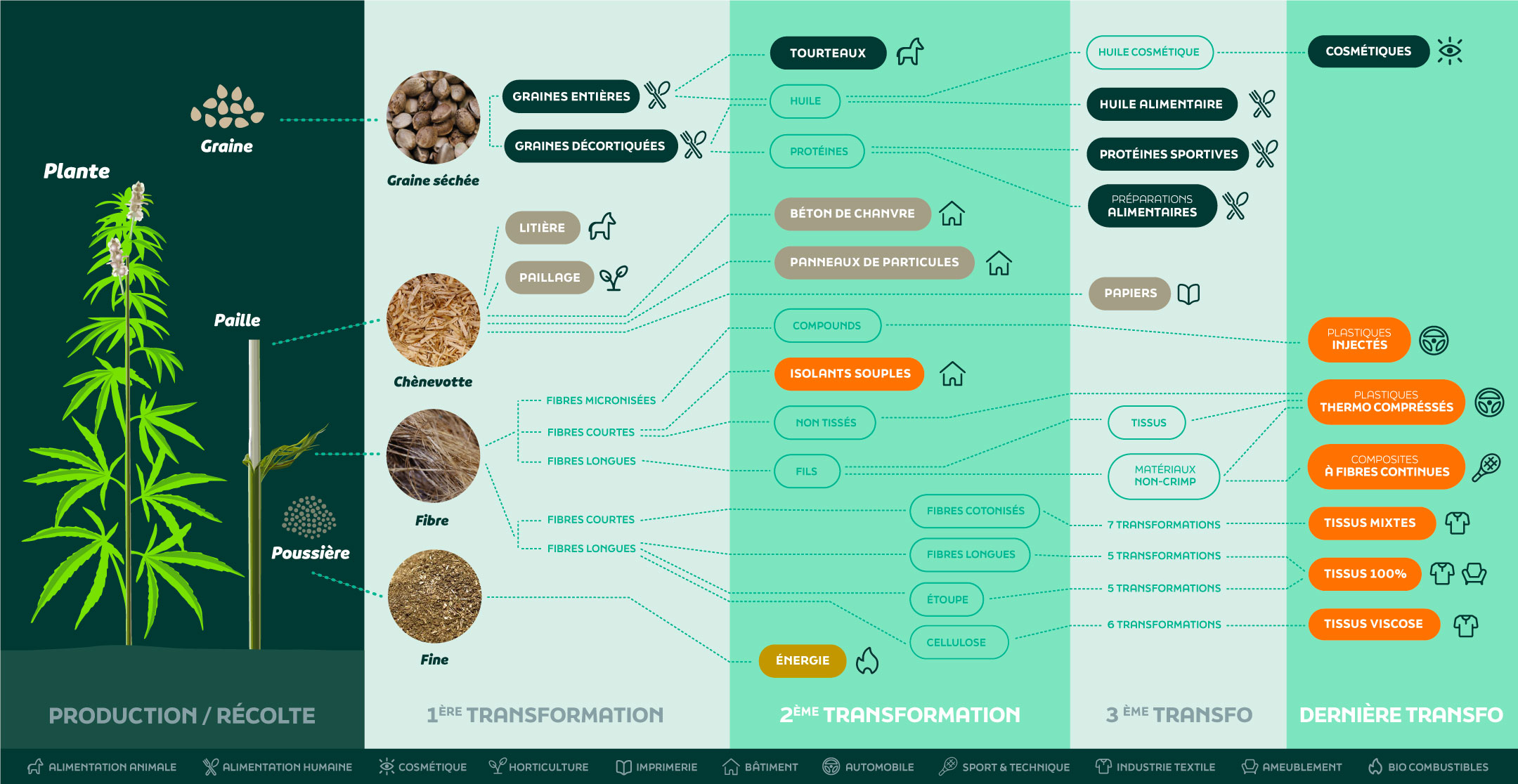

La graine de chanvre, également appelée chènevis, représente 11 % du poids de la plante et 21 % de sa valeur économique. Triée et calibrée, elle peut être transformée par la chanvrière en graine entière ou décortiquée, en huile, en farine ou en tourteaux. La part de marché de la graine de chanvre dans l’alimentation humaine est en forte croissance, car elle est considérée comme un aliment santé en raison de ses qualités nutritionnelles exceptionnelles. Les autres débouchés du chènevis concernent les secteurs de l'oisellerie et de la pêche.

La chènevotte représente 44 % du poids de la plante et 27 % de sa valeur économique. Elle est obtenue à partir de la partie centrale ligneuse de la tige et transformée en granulat calibré selon son usage futur. Ces granulats sont particulièrement bien valorisés dans la construction pour produire du béton de chanvre, un matériau prisé en écoconstruction pour ses performances en termes d'isolation, d'inertie thermique, de régulation hygrométrique et de bilan carbone. Ils sont également couramment utilisés comme litière animale ou paillage horticole.

La fibre de chanvre, représentant 24 % du poids de la plante et 50% de la valeur économique, est extrêmement résistante et utilisée dans divers domaines : textile, papeterie, bâtiment et plasturgie. Le marché textile est le plus prometteur, car le chanvre est 100 % naturel, contrairement aux textiles actuels. Les chanvrières transforment la fibre en différentes catégories (longue, semi-longue, courte, cellulosique) pour l'intégrer aux systèmes de filature existants (lin, laine, coton, produits cellulosiques).

La poussière ou fine de chanvre représente 21 % du poids de la plante, mais seulement 2 % de sa valeur économique. Ce troisième produit issu du défibrage est composé de petites particules de fibre et de chènevotte, ainsi que de matières minérales. 80 % de cette poudre est utilisée sous forme compressée pour produire de l'énergie dans des chaudières industrielles, tandis que les 20 % restant servent de compost ou à d'autres usages.

transformées

La chènevotte utilisée pour fabriquer le béton de chanvre relève du label "Label granulat chanvre". Ce label s'inscrit dans une démarche de qualité définie dans les Règles Professionnelles et permet de réaliser tous types de bâtiments : logements individuels et collectifs, tertiaires, etc.

de particules

Le panneau de particules à base de chanvre est écologique, léger et résitant. Sa structure respirante régule l’humidité, réduisant les risques de moisissures, tout en offrant une alternative durable aux panneaux traditionnels.

La laine de chanvre est un substitut très performant aux isolants traditionnels issus du pétrole. Ses qualités thermiques, acoustiques et hypoallergéniques en font un matériau idéal qui contribue au confort intérieur.

La fibre courte permet d’adapter la fibre de chanvre aux machines de production de coton et de produire des textiles mélangeant le chanvre à une autre fibre (coton, lyocelle, etc).

La fibre semi-longue permet d’adapter la fibre de chanvre aux machines de production de la laine et permet de produire des fils 100% chanvre plus grossiers notamment pour l’ameublement.

La fibre Longue permet d’utiliser les mêmes techniques de filature que le lin et permet de produire des fils naturels et 100% chanvre utilisés dans la confection et l’ameublement.

La fibre cellulosique permet de produire des fibres textiles légères et résistantes, offrant une alternative aux matériaux dérivés du pétrole pour les vêtements, les textiles techniques ou les composites.

Les compounds, composites en granulés, sont obtenus en mélangeant une matrice de résine (biosourcée ou non) avec des fibres de chanvre micronisées. Ils permettent de fabriquer des pièces en plastique injecté.

La graine décortiquée est utilisée pour l’alimentation. Ses qualités nutritives et son goût en font un ingrédient sain et créatif pour de nombreuses recettes.

L’huile de chanvre est obtenue par extraction à froid. La purification est réalisée par décantation et filtration sans procédé chimique. Sa texture est très fluide et son profil lipidique est riche en oméga 3.

Les graines de chanvre, complètes ou décortiquées, sont d’abord broyées et déshuilées. La protéine sèche est alors finement moulue pour obtenir une poudre aux très grandes qualités nutritives.

Les tourteaux sont obtenus après pressage des graines pour la fabrication de l’huile de chanvre. Ils sont utilisés dans l’alimentation animale pour leur haute qualité en protéines.

& briquettes

Les briquettes de poussière de chanvre compressée représentent, pour le secteur industriel, une ressource renouvelable alimentant les producteurs d’énergie du territoire.

leurs utilisations

TRANSFORMATION

DU CHANVRE

& publications