UTILISER

LE CHANVRE

1000 usages

ÉCO-CONSTRUCTION

Le secteur de la construction conventionnelle est extrêmement énergivore, polluant et gourmand en ressources non renouvelables, sans recours aux circuits courts. Une alternative plus vertueuse réside dans l’éco-construction et l’utilisation de matériaux biosourcés, notamment à base de chanvre. Cultivé en France, le chanvre est produit et mis en œuvre selon des techniques respectueuses de l’environnement. En outre, les matériaux en chanvre offrent des performances remarquables, permettant de réduire l’empreinte carbone et de promouvoir la sobriété énergétique des bâtiments.

Le béton de chanvre possède notamment d’excellentes caractéristiques thermiques, offrant un confort optimal en hiver comme en été, ce qui permet de réaliser jusqu’à 70% d’économies de chauffage (Étude Cerema). Il régule l’humidité, améliore la qualité de l’air ambiant et isole phoniquement grâce à la structure poreuse de la chènevotte. Offrant une excellente résistance au feu EI 240 (Essais CEF 2019), il n’attire également pas les rongeurs.

Issus d’une culture respectueuse de l’environnement, les matériaux à base de chanvre sont biosourcés et renouvelables, offrant des solutions innovantes pour la construction et la rénovation. La filière favorise le circuit court grâce à la proximité entre producteurs et sites de transformation. De plus, les matériaux en chanvre captent le CO2 : 1 m² de mur en béton de chanvre de 35 cm stocke 38 kg de CO2, contre 100 kg émis par un mur en parpaing avec isolant.

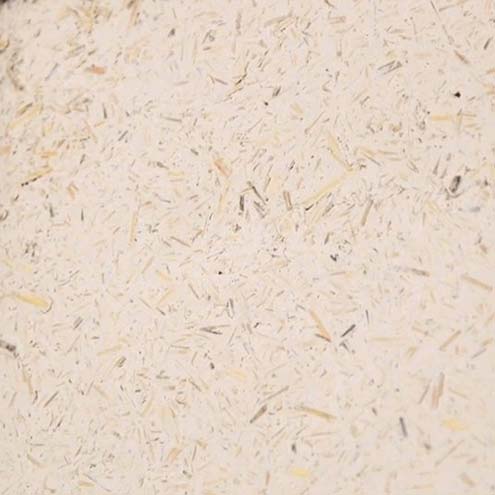

Le béton de chanvre est composé de granulats de chanvre labellisés (chènevotte), d’un liant et d’un peu d’eau. Il est utilisé pour réaliser des murs isolants et des cloisons en neuf ou en rénovation de bâtiment. Matériau léger, il est facile à mettre en œuvre par remplissage d’une ossature porteuse, préférentiellement en bois, soit par voie humide, soit par voie sèche à partir d’éléments préfabriqués. Le béton de chanvre offre une excellente stabilité sismique.

La laine de chanvre est utilisable en rénovation comme en neuf, en panneaux semi-rigides ou en rouleaux. Elle offre d’excellentes propriétés thermiques et acoustiques. Grâce à sa perméabilité à la vapeur d’eau, elle régule l’hygrométrie et est imputrescible, contribuant ainsi à sa longévité et à un confort intérieur optimal. Facile à installer et non irritante, la laine de chanvre est également résistante aux insectes et aux rongeurs, ce qui en fait une solution durable et saine pour l’isolation des bâtiments.

Les enduits en chanvre sont généralement composés de chènevotte et d’un liant à base de chaux, avec l’ajout éventuel d’autres composants pour améliorer certaines propriétés. Ces enduits peuvent être appliqués en forte épaisseur pour des reprises de mur. Ils contribuent à améliorer sensiblement le confort thermique et acoustique. Leur bonne perméabilité à la vapeur d’eau favorise la perspirance des murs en béton de chanvre, essentielle pour garantir une régulation optimale de l’humidité et un environnement intérieur sain.

textile

Pour le chanvre, le marché textile représente un fort potentiel et l’une des meilleures valorisations de la fibre. Contrairement à l’industrie textile actuelle, grande consommatrice d’eau, de pesticides et de produits pétro-sourcés, le chanvre permet de produire des textiles 100 % naturels. La France, premier producteur en Europe, dispose d’un savoir-faire unique et bénéficie du Label France Hemp Fiber, garantissant notamment des fibres sans traitements phytosanitaires.

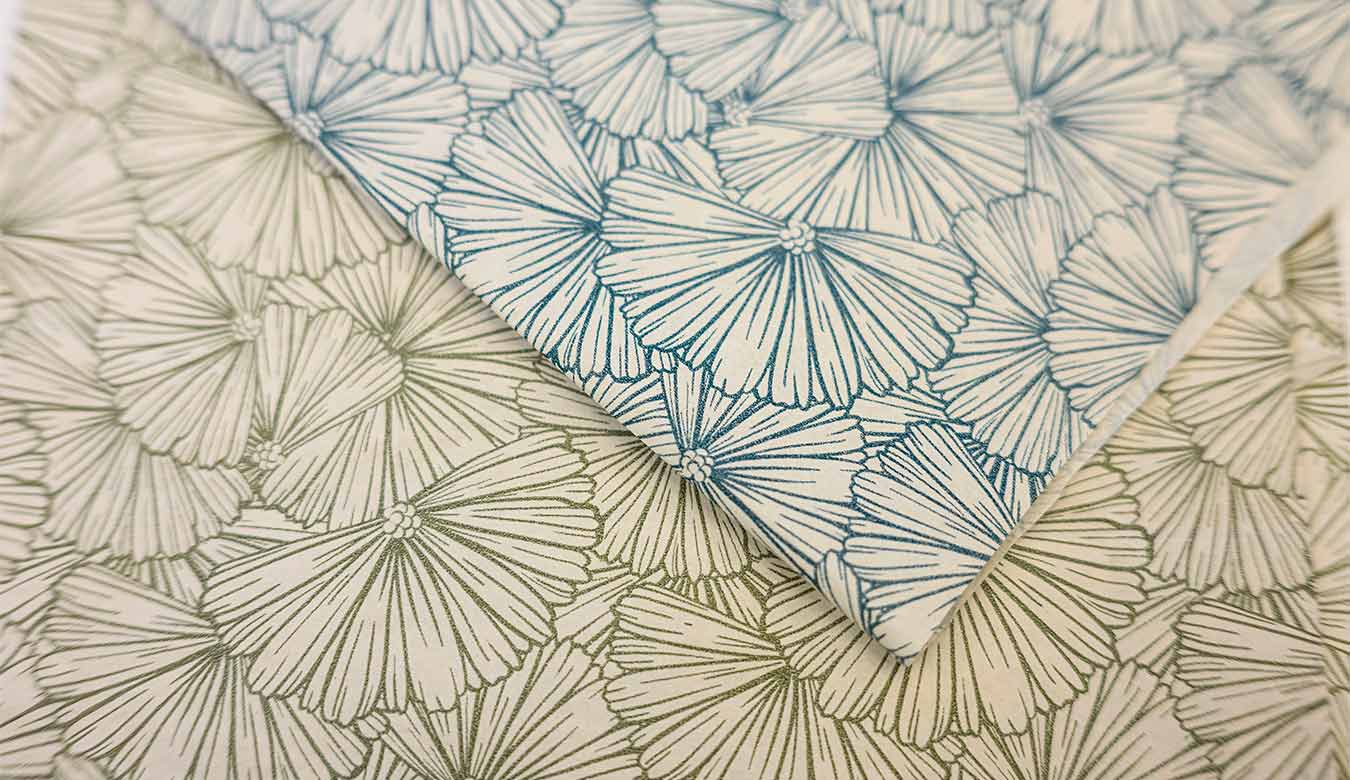

La fibre de chanvre est transformée par les chanvrières sous différentes dimensions pour l’adapter aux modèles d’affinage existants utilisés pour le lin, la laine, le coton et les fibres cellulosiques, car il n’existe plus actuellement d’outillage spécifique au chanvre. Les textiles à base de chanvre présentent des qualités aujourd’hui recherchées par les consommateurs : authenticité, résistance, recyclabilité, ainsi que d’excellentes propriétés thermorégulatrices et absorbantes.

La technique d’affinage utilisant des fibres courtes, entre 3 et 5 cm, appelée « cotonisation », permet au chanvre de s’adapter aux machines de production du coton déjà existantes et d’être intégré en mélange avec d’autres fibres à des pourcentages variables. Cette facilité d’utilisation industrielle intéresse des grandes marques comme Levis, Décathlon ou Ikea, qui développent des textiles à base de chanvre pour le substituer aux fibres plus nocives. Cela répond à la demande des consommateurs pour des vêtements plus responsables.

Chanvre cotonisé

Cette technique d’affinage innovante, en phase de développement, consiste à produire des fibres de chanvre de 20 à 40 cm pour leur permettre d’être transformées par des outils d’affinage destinés à la laine. Ces fibres sont utilisées pour fabriquer des fils 100 % chanvre plus grossiers pour l’ameublement, les bagages et la ficellerie.

La technique d’affinage de la fibre de chanvre longue suit le même processus que celui du lin, en utilisant notamment les techniques de rouissage au champ, de teillage et de filature pour obtenir des fils 100 % chanvre. Une fois tissés, ces fils produisent un tissu naturel qui sera ensuite ennobli (teinté, imprimé) pour être utilisé dans le secteur de la confection ou de l’ameublement, créant ainsi un produit 100 % chanvre.

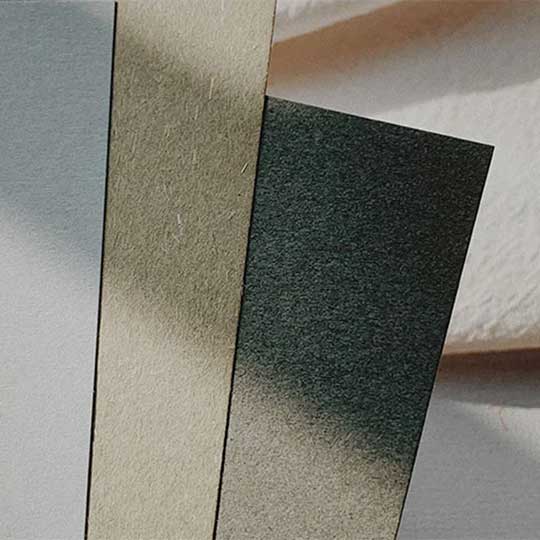

Cette technique, utilisée pour produire des textiles à base de viscose ou de lyocell à partir de la cellulose de bois, est développée pour le chanvre avec la chènevotte en France depuis 2018. L’intérêt principal réside dans sa capacité à fournir des fibres polyvalentes présentant des qualités techniques telles que la finesse, la résistance et la légèreté. Le chanvre cellulosique peut remplacer les produits dérivés du pétrole pour la production de textiles, vêtements ou de textiles techniques.

biosourcée

L’industrie de la plasturgie, soucieuse de réduire son impact environnemental, cherche à intégrer des fibres naturelles dans sa production. Les techniques actuelles permettent des applications à grande échelle, notamment dans l’automobile, où les fibres de chanvre offrent de hautes performances. D’autres secteurs, comme le bâtiment, développent des solutions biosourcées pour les lattes de terrasse et le bardage. Les fibres végétales, renouvelables, réduisent l’utilisation de produits issus du pétrole. Leurs principaux avantages sont la légèreté, les performances mécaniques ainsi que la possibilité de recycler.

biosourcés

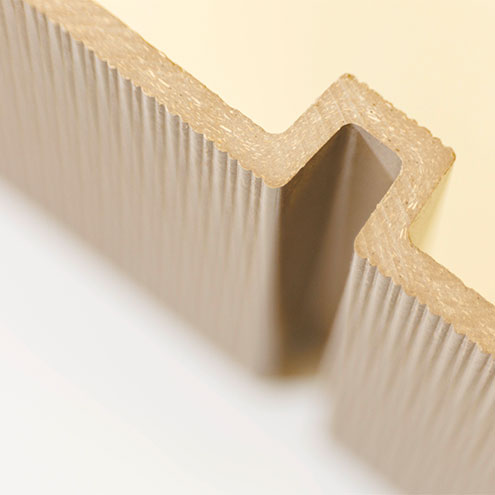

Ces plastiques sont fabriqués à partir de compounds (composites en granulés) obtenus en mélangeant la fibre de chanvre avec un polymère et des additifs. Fondus et injectés dans des moules, ils permettent de créer des pièces complexes et légères. Ils sont utilisés pour produire des tableaux de bord et des rétroviseurs ou, par extrusion, pour produire des pièces longues : lames de terrasse ou des profilés d’huisserie.

compressés biosourcés

Les plastiques thermo compressés biosourcés sont fabriqués à partir de fibres de chanvre transformées en non-tissés par la technique de nappage et d’aiguilletage, mélangées à des polymères thermofusibles. Une fois compressés à chaud pour obtenir la forme désirée, ils sont utilisés dans l’industrie automobile pour fabriquer des pièces légères, telles que des intérieurs de portes ou des tablettes de coffre.

Les plastiques composites à fibres continues sont constitués d’une matrice pour la cohésion, associée à un renfort en fibres, généralement de verre ou de carbone. Les fibres végétales apportent de nouvelles qualités : légèreté, capacité d’amortissement et esthétique. Depuis une dizaine d’années, des produits comme les skis, surfs, vélos, casques, raquettes de tennis, guitares et meubles de luxe intègrent ces fibres végétales.

compressés biosourcés

Les plastiques thermo compressés biosourcés sont fabriqués à partir de fibres de chanvre transformées en non-tissés par la technique de nappage et d’aiguilletage, mélangées à des polymères thermofusibles. Une fois compressés à chaud pour obtenir la forme désirée, ils sont utilisés dans l’industrie automobile pour fabriquer des pièces légères, telles que des intérieurs de portes ou des tablettes de coffre.

alimentaire

Les volumes de chènevis ou graine de chanvre destinés à l’alimentation humaine sont en croissance constante, et pour une excellente raison : le chanvre possède des qualités nutritionnelles remarquables. Ce super-aliment, sans OGM et sans gluten, convient à la plupart des régimes alimentaires. En plus de ses qualités nutritionnelles, il ne contient aucune trace de produits phytosanitaires, ceux-ci étant inutiles à sa culture.

La graine de chanvre, qu'elle soit entière ou décortiquée, possède toutes les qualités d'un aliment santé. Elle est riche en protéines, acides gras essentiels, oméga-3, fibres, cuivre, fer, magnésium, manganèse, phosphore, potassium, zinc, vitamines B1 et B6, et constitue également une bonne source de calcium.

L’huile de chanvre présente un profil lipidique idéal, riche en acides gras essentiels comme les oméga-3 et oméga-6, avec un rapport proche de 4:1. Ces acides gras polyinsaturés aident à réduire le cholestérol et à prévenir les maladies cardiovasculaires.

La graine de chanvre, riche en protéines (25 % pour la graine entière et jusqu’à 60 % dans les farines obtenues à partir de graines déshuilées et sans coque), est l’un des rares végétaux à contenir les huit acides aminés essentiels. Cela en fait une excellente protéine végétale, idéale pour remplacer les protéines animales.

naturels

Baumes, crèmes ou huiles, la gamme des cosmétiques à base de chanvre est étoffée. C’est principalement l’huile de graine de chanvre qui entre dans leur composition : elle est riche en omega 3, omega 6 et en vitamine E. Elle est reconnue depuis toujours pour ses pouvoirs hydratants, sa capacité à renforcer la barrière hydrolipidique de la peau. L’huile de chènevis est une huile sèche qui pénètre rapidement sans laisser de film gras. Depuis l’antiquité, on lui attribue de nombreux pouvoirs anti-inflammatoire, anti-atopique, cicatrisant et antiradicalaire.

& responsable

La fibre de chanvre contient généralement entre 70 % et 85 % de cellulose, ce qui en fait une matière première idéale pour la production de papier. À surface égale, le chanvre produit quatre fois plus de papier que le bois et nécessite moins de traitement. Les papiers de chanvre sont écologiques, de haute qualité et résistants, et sont utilisés pour le papier d’art, technique, filtre, cigarette, etc. Le premier ouvrage imprimé (la Bible de Gutenberg) a été réalisé sur du papier de chanvre.

animale

La chènevotte possède un pouvoir d’absorption exceptionnel, capable de retenir 4 à 5 fois son poids en eau sans varier de volume, ce qui en fait un matériau idéal pour la litière animale. Naturelle, isolante et sans poussière, elle offre un confort sain et agréable pour les animaux ; elle est recommandée par les vétérinaires. De plus, elle est facile à nettoyer et compostable, pouvant ainsi être utilisée comme engrais.

horticole

Les caractéristiques de la chènevotte en font un matériau idéal pour le paillage horticole. Son utilisation empêche la croissance des mauvaises herbes et préserve l’humidité du sol. Disponible en vrac ou compacté sous forme de galette, il est distribué dans toutes les chanvrières de la filière et dans les bonnes jardineries. Les toiles géotextiles de chanvre non tissé, réalisées à base de fibres, proposent, quant à elles, une autre solution de couvert végétal biodégradable, qui permet d’éviter le désherbage et de réduire l’évaporation de l’eau.

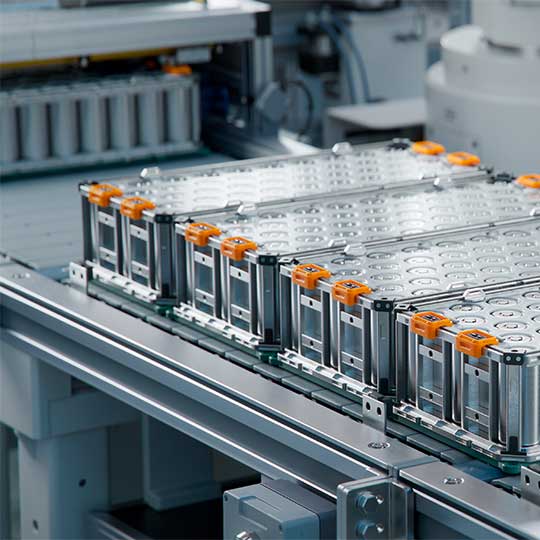

du chanvre

Le chanvre possède déjà de nombreuses applications industrielles, mais de nouvelles solutions restent à explorer, comme pour les batteries de voitures électriques, les composites pour bateaux et trains, les adhésifs, le packaging, et même le plasma sanguin. Dans les domaines déjà exploités, les possibilités de diversification sont vastes, comme l’utilisation du chènevis dans les substituts de viande et l’alimentation végétarienne. Les besoins sociétaux, les avancées techniques et les investissements ouvriront de nouveaux débouchés pour cette plante pleine de ressources surprenantes, encore à découvrir.